As a pioneer in Friction Stir Welding (FSW), Mazak MegaStir specializes in finding ways to remove challenging materials from the impossible-to-join list, creating defect-free joints with greater strength than conventional welds. Within the Mazak HYBRID Multi-Tasking family of machine tools, FSW technology often holds the key to breakthroughs in production for aerospace, electronics, energy production and shipbuilding. For manufacturers in the oil and gas industry in particular, recent tests show that FSW can offer excellent results in several welding applications, especially those involving tough X80 steel.

The American Petroleum Institute (API) approves X80 steel for oil and gas applications and classifies it through API Specification 5L. Many companies produce this alloy, which offers a minimum yield strength of 80 kpsi (555 MPa). This leading property of pipeline steel defines the amount of tensile stress that elongates the metal by 0.5%, and refers to the relationship between stress applied to the metal and the strain that results from the stress.

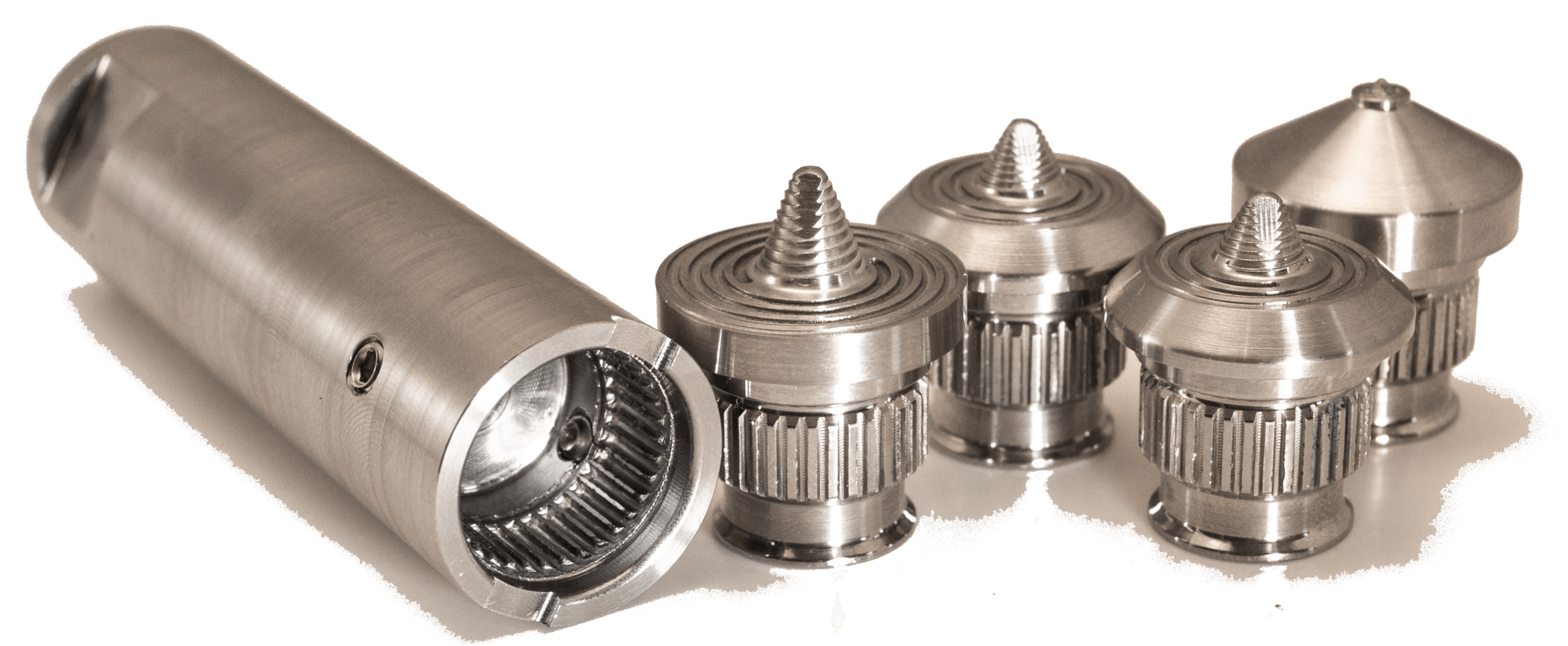

Because X80 is a high grade of low-carbon pipeline steel, it can be difficult to weld. Mazak MegaStir conducted a Friction Stir Welding test of X80 steel with an alloy chemistry incorporating 0.18% carbon, 1.80% manganese, 0.03% phosphorus and 0.018% sulfur. The test used a 12″-square specimen of flat X80 plate sectioned in half along the rolling direction. Sanding removed oxidation and scale, and degreasing used a methanol solvent. Because no previous data existed to determine mechanical properties and welding forces, Mazak MegaStir used conservative process parameters.

X80 Steel: Mazak MegaStir Friction Stir Welding (FSW) Test

| Material Description | Thickness | 0.25″ (6.4 mm) |

| Process Parameters | Spindle Speed | 550 rpm |

| Feed Rate | 4 ipm (102 mm/min) | |

| Head Tilt | 3.5° | |

| Shielding Gas | Argon | |

| Gas Flow Rate | 50 cfh (23.6 l/min) | |

| Coolant Flow Rate | 0.85 gal/min (0.4 l/min) | |

| Control Mode | Position |

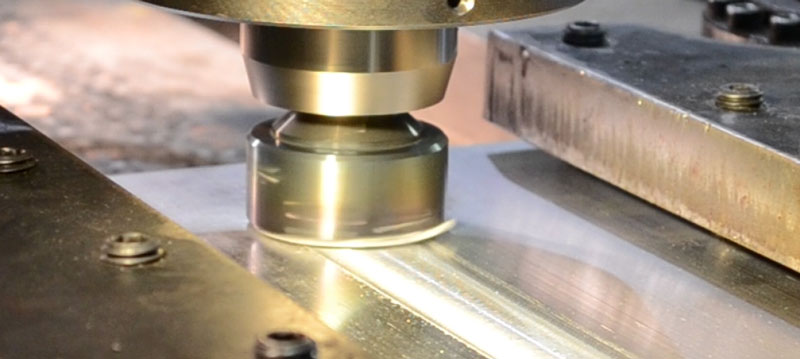

For this initial partial-penetration butt welding test of X80 steel, Mazak MegaStir measured load data from the X and Z axes, along with temperature readings from a thermocouple behind the FSW tool’s PCBN shoulder. To prevent oxidation during the weld cycle, the test used an argon gas atmosphere. Evaluation of the results showed that the weld produced an excellent profile, with good flow of material under the shoulder of the tool. Because axis forces remained low, Mazak MegaStir was able to optimize the material’s rate of travel in relation to the mechanical strength of the tool. Post-procedure testing of the microstructure revealed a fully consolidated weld with a large area of flow around the pin of the FSW tool.

Successful FSW testing with X80 steel shows that FSW holds the potential to optimize microstructures and mechanical properties in this challenging metal. In their standard configurations, current Mazak HYBRID Multi-Tasking machines with FSW capabilities can weld all series of aluminum alloys, all aluminum metal matrixed materials and some copper alloys. Customers who need the ability to join X80 or D2 steel can achieve these results on Mazak HYBRID Multi-Tasking equipment configured with specially modified FSW capabilities, adding process ease and speed to new realms of manufacturing.