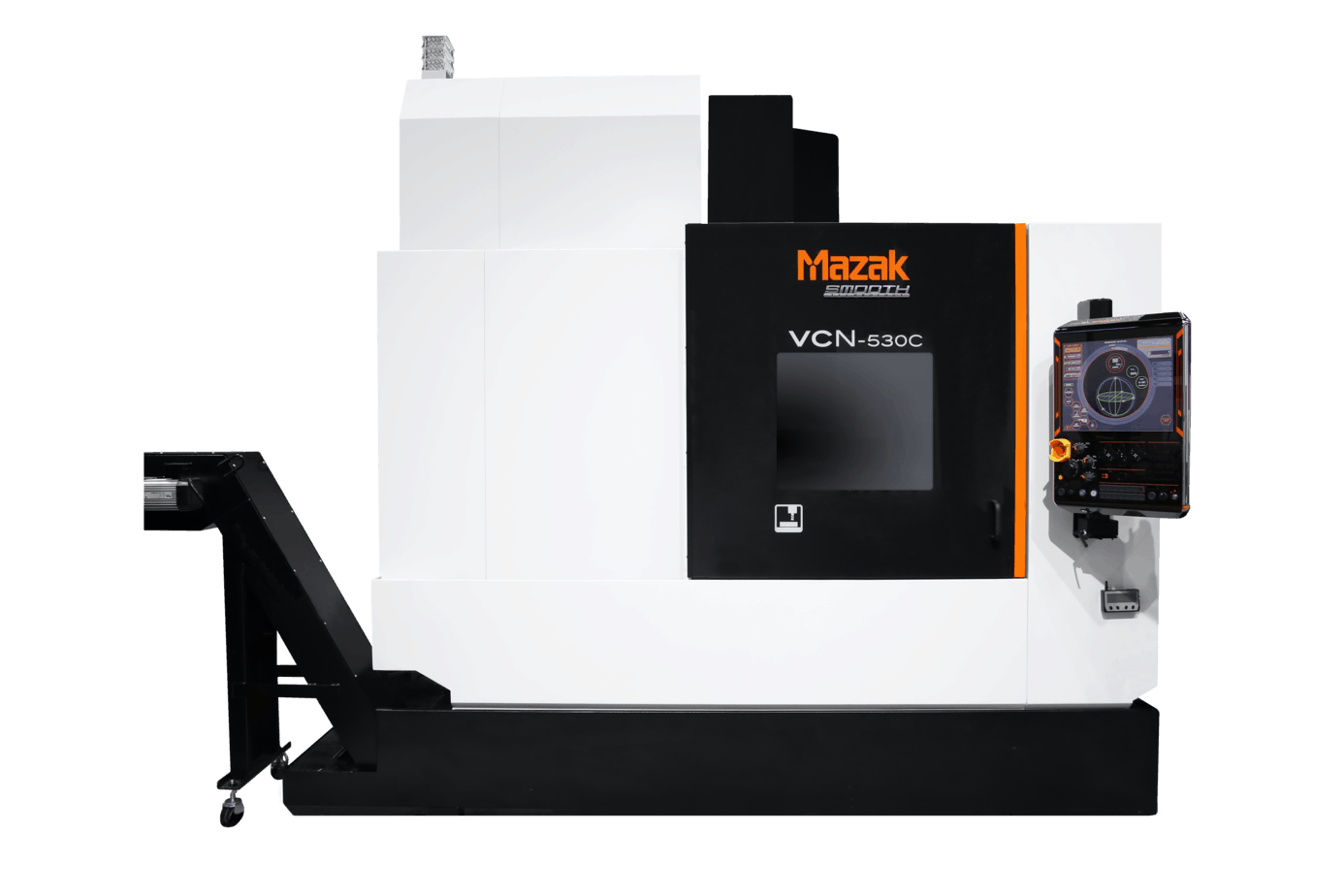

Machines - Mazak MegaStir

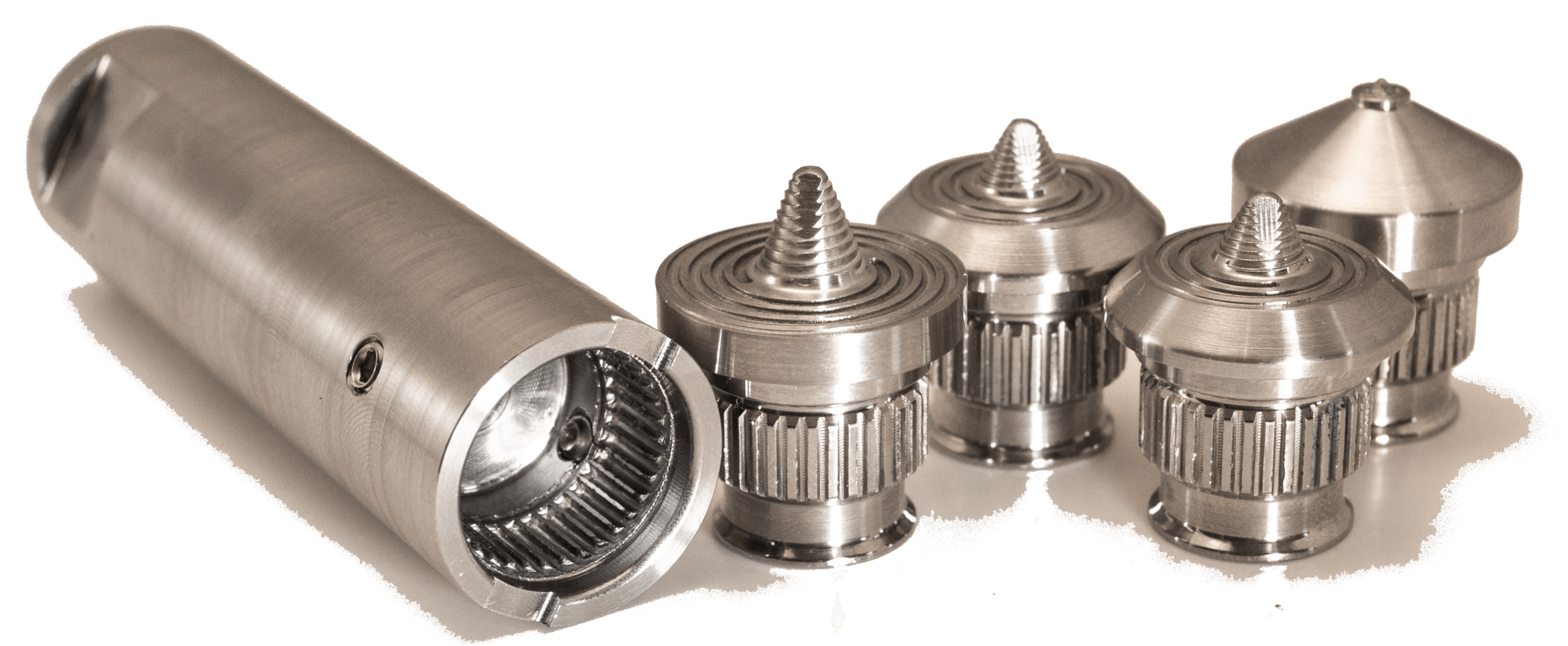

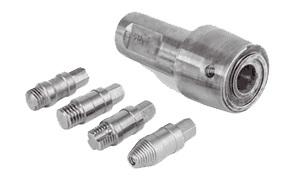

The Mazak FSW Series of HYBRID Multi-Tasking systems combines subtractive multi-axis machining with FSW joining capabilities pioneered by Mazak MegaStir. The FSW process uses a solid-state combination of frictional heat with forging pressure to create lighter-weight parts and pure, clean joints that are stronger, higher quality and more durable than MIG welding and other options can generate. FSW also requires less electricity than other options and eliminates the material weakening that can occur with conventional welding.

HYBRID Multi-Tasking with FSW capability is particularly well suited to semiconductor production as well as in the manufacture of batteries, battery trays and vehicles, especially hybrid and electric models.

Like all Mazak Multi-Tasking solutions, FSW machines complete most or all of a part’s machining in one cycle, significantly reducing setup times. Because the entire welding process takes place in a single pass without depositing multiple layers of added metal, it dramatically simplifies the processes of repairing welded parts and joining dissimilar metals.

User-friendly human/machine interface (HMI) software makes the FSW Series easy for shops to learn and use, with real-time monitoring that enables operators to adjust thrust force and material temperature on the fly directly through Mazak’s MAZATROL SmoothG CNC controller. Additionally, the software records all data from the operation and charts the actual process involved in producing a part.

Download the Mazak Megastir Brochure

WHAT SOLUTION IS RIGHT FOR YOUR PROJECT?

Achieve a better weld today with full-function Friction Stir Welding technology from Mazak MegaStir.