Automotive - Mazak MegaStir

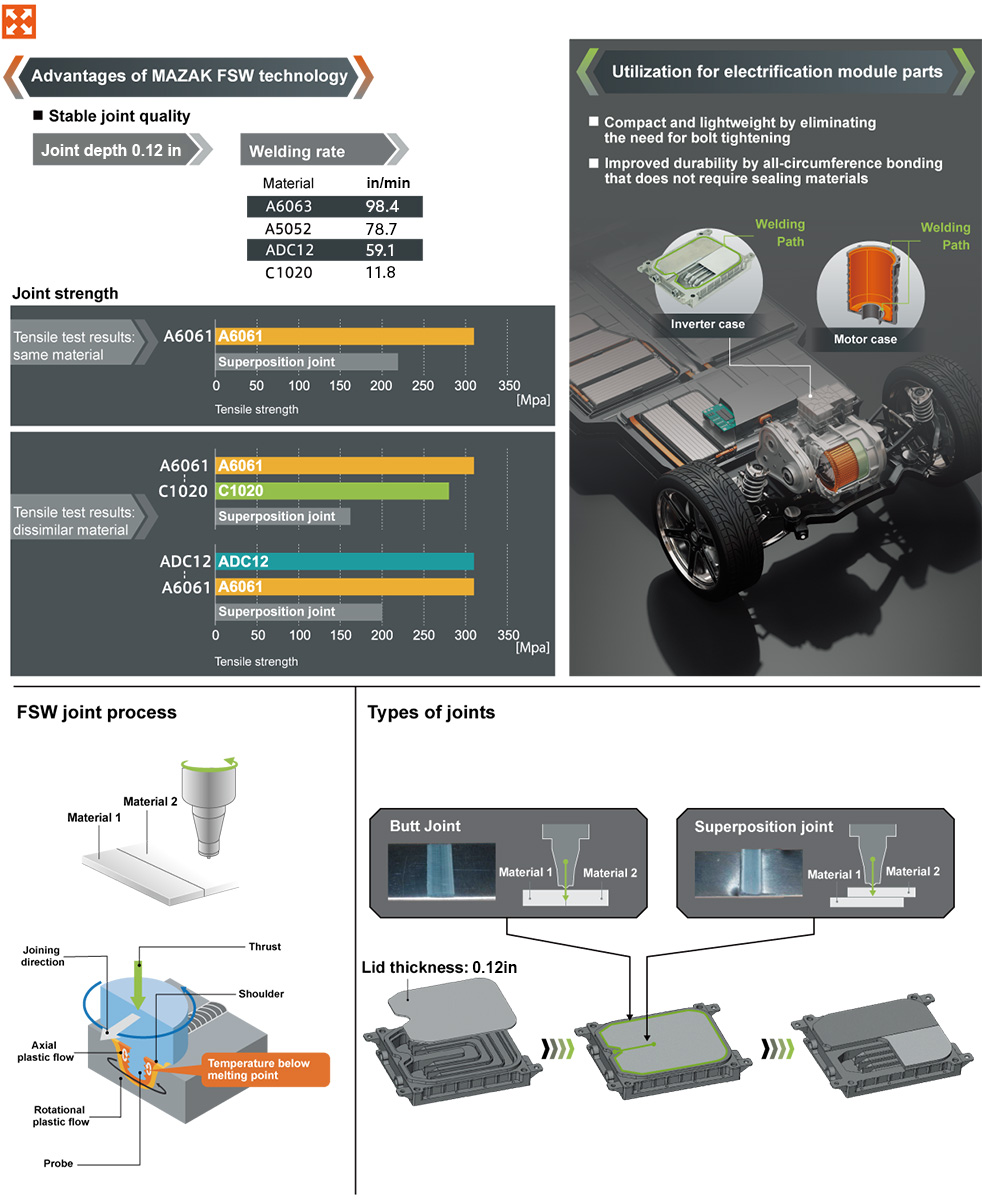

As the automotive industry increases its use of aluminum to help improve fuel efficiency, FSW offers many potential benefits. In contrast to most other joining processes, Friction Stir Welding can handle the variations inherent in high-volume production at the same time it provides improved mechanical properties.

In all of the industries served by Mazak MegaStir, FSW has distinct benefits and cost savings that make it superior to alternatives. In the automotive sector, the increased pressure on auto manufacturers to step up their development of greener, more fuel-efficient vehicles capable of meeting increasingly strict fuel economy standards has required the development of lighter, more efficient car bodies.

With Friction Stir Welding, manufacturers can easily avoid problems such as the porosity in casting assemblies, which creates significant scrap due to frequent defects. Instead, FSW can pass or raster through affected areas to resolve defects and improve material properties with a more refined gain. And by joining thinner high-strength automotive steels, aluminum and magnesium alloys, automakers can reduce weights far below what was once thought possible.

Interest among automakers has resulted in the successful use of FSW technology for such applications as:

Mazak MegaStir + EV Applications

Case Study

Download the Mazak Megastir Brochure

WHAT SOLUTION IS RIGHT FOR YOUR PROJECT?

Achieve a better weld today with full-function Friction Stir Welding technology from Mazak MegaStir.