Since the 1970s, Mazak has manufactured advanced machining technology at our Florence, Kentucky-based campus here in the heartlands. Through the years, our U.S. headquarters has become one of the most technologically sophisticated manufacturing facilities in the world – and the hub of a global network of Technology and Technical Centers that gives customers access to Mazak’s world-class service and support. And now, through our 360º Virtual Campus Tour, it’s easier than ever for you to see how the team at Mazak uses our infrastructure to support your shop.

Part of Mazak Interactive, our new range of digital experiences, the new virtual tour uses 360° video, complete audio narration and VR-device compatibility to bring the campus to your device. You get the full virtual VIP treatment, starting with a welcome from Mazak President Dan Janka and extending throughout the tour, as we take you through the Mazak iSMART Factory™, National Technology Center and North American Parts Center.

The factory floor is the star of the show. From welding and laser processing to final assembly and shipping, you can experience the entire part-production process, as we use Mazaks to build Mazaks. You’ll also see our automation systems, including a full PALLETECH System linking together dissimilar machines for fully automated lights-out production.

And beyond the excitement of the Mazak iSMART Factory, the rest of our campus is well worth the visit. The National Technology Center brings together some of the most experienced Mazak applications engineers, CNC programmers and machining specialists to help our customers solve their toughest challenges. Whether it’s classes at the National Learning Center, a seminar in our MAZATROL Lab or a visit to the Center for Multi-Tasking and Manufacturing Excellence, you’ll see why so many Mazak customers make the team at the National Technology Center their partners in the pursuit of manufacturing success.

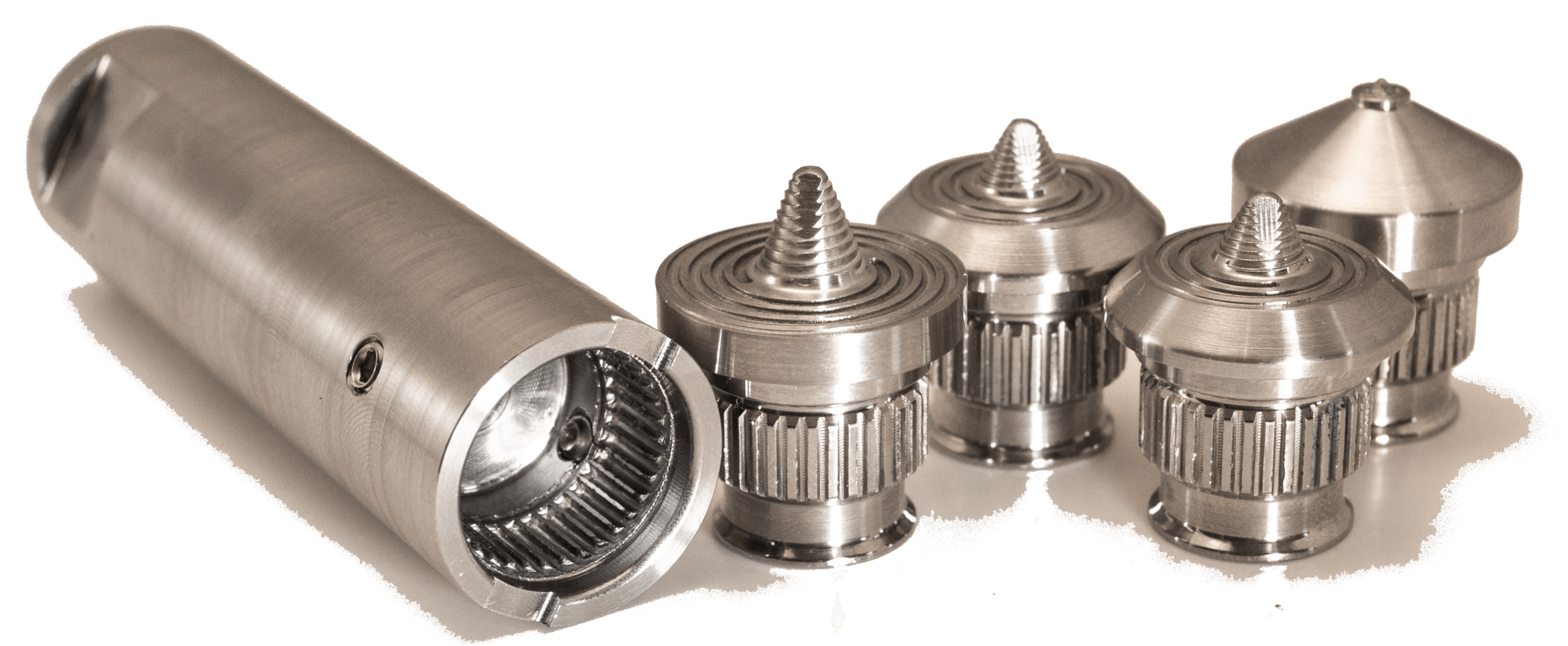

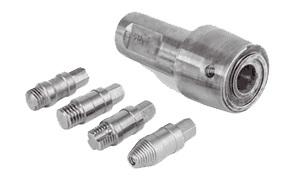

Of course, manufacturing success requires consistency, reliability and uptime – and at the North American Parts and Spindle Rebuild Center, you’ll see how we maximize our customers’ productivity. Our 97% same-day shipping rate relies on the tens of thousands of unique parts we keep stored in an advanced vertical storage/retrieval system, while our new Spindle Rebuild Department has the experience and resources to handle more than 100 rebuilt spindles per month.

Even if you’ve visited our Kentucky campus before, you’re almost certain to see new developments on the virtual tour, such as the new MAZATEC Smart Manufacturing System (SMS) installation that links together multiple horizontal machining centers and Multi-Tasking Mazak machines, or the recently completed expansion of the Spindle Rebuild Department. Take a look at our virtual tour today – and if you want to see even more, reach out to your local Mazak representative for information on scheduling an in-person visit to Florence. We look forward to seeing you!